XY-190-C Water well drilling rig

Water well drilling rigs are specialized mechanical setups engineered to drill into the earth to access subterranean water. These rigs are crucial in various sectors, including agriculture, residential, industrial, and environmental management.

- XY-190-C

- ZHUOXIN

- Water well drilling rig

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Reverse Circulation (RC) Drilling Rigs: Specialized for deep wells, these rigs allow for faster drilling by pumping drilling fluid down around the outside of the drill pipe and up through the center.

描述

Water well drilling rigs are specialized mechanical setups engineered to drill into the earth to access subterranean water. These rigs are crucial in various sectors, including agriculture, residential, industrial, and environmental management.

Varieties of Water Well Drilling Rigs

Hydraulic Rotary Drilling Rigs: Utilize hydraulic systems to power the rotary drill. These are known for their efficiency and are often used in hard rock formations.

Auger Drilling Rigs: Employ a helical screw to be drilled into the ground. Ideal for softer soil conditions and shallow wells.

Reverse Circulation (RC) Drilling Rigs: Specialized for deep wells, these rigs allow for faster drilling by pumping drilling fluid down around the outside of the drill pipe and up through the center.

Principal Components

Drilling Mast: Provides the vertical structure for the drilling operation, crucial for guiding the drill string.

Drill String and Collars: A series of pipes and heavy weights that provide pressure for drilling.

Drill Bits: Designed according to the geological structure, these vary from diamond-tipped bits for hard rock to softer bits for soil.

Mud Systems: Critical for lubricating the drill bit, stabilizing the well walls, and removing cuttings.

Power Unit: Often diesel engines, though some rigs use electric or hybrid systems.

Drilling Techniques

Rotary Drilling: The most common method, involving a rotating drill bit and the circulation of drilling mud.

Percussion Drilling: Uses a hammering action to break the earth, suitable for rocky terrains.

Directional Drilling: For accessing water resources under obstacles or in environmentally sensitive areas.

Applications

Rural and Urban Water Supply: Critical for providing water in both urban and rural settings.

Irrigation Systems: Essential for agriculture, especially in arid regions.

Industrial Processes: Many industries rely on large quantities of water sourced through these rigs.

Safety and Sustainability

Safety Standards: Rigorous standards and protocols are necessary to ensure the safety of operators.

Environmental Considerations: Measures to minimize the impact on the local ecosystem, including careful management of drilling by-products.

Technological Innovations

Advancements in automation, telemetry, and environmental safeguards have significantly improved the efficiency and reduced the environmental impact of these rigs.

In summary, water well drilling rigs are complex, highly specialized machines designed for accessing one of our most vital natural resources: water. They represent a convergence of engineering, environmental science, and practical know-how, playing a pivotal role in sustaining human activities across the globe.

Varieties of Water Well Drilling Rigs

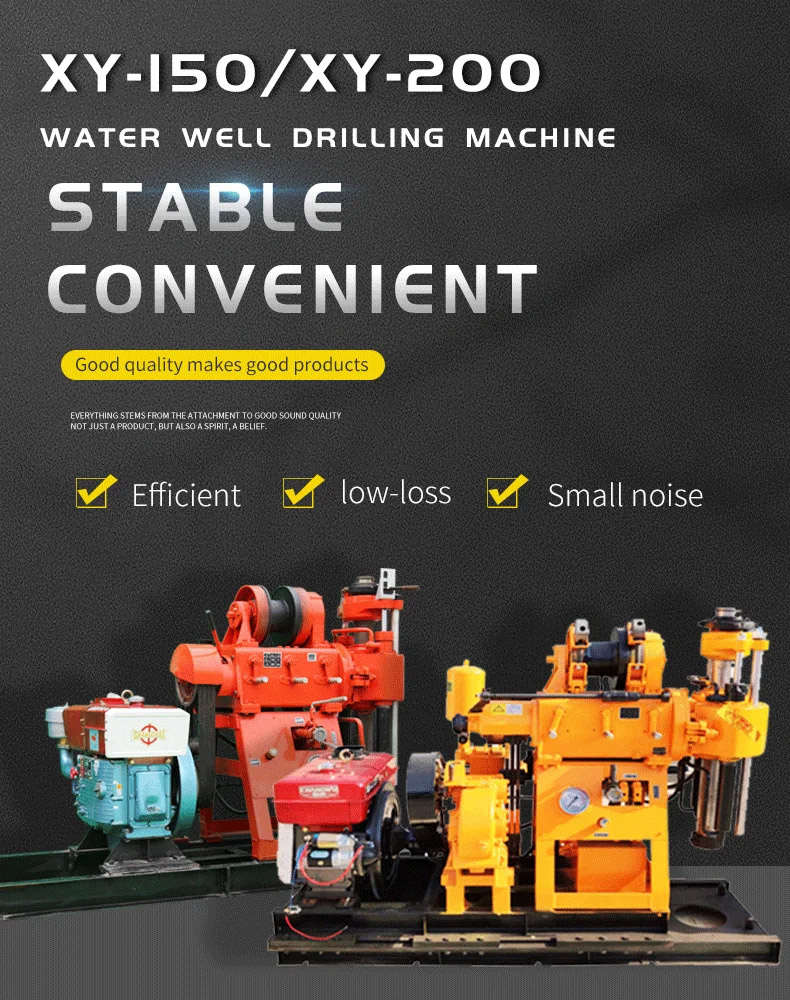

Hydraulic Rotary Drilling Rigs: Utilize hydraulic systems to power the rotary drill. These are known for their efficiency and are often used in hard rock formations.

Auger Drilling Rigs: Employ a helical screw to be drilled into the ground. Ideal for softer soil conditions and shallow wells.

Reverse Circulation (RC) Drilling Rigs: Specialized for deep wells, these rigs allow for faster drilling by pumping drilling fluid down around the outside of the drill pipe and up through the center.

Principal Components

Drilling Mast: Provides the vertical structure for the drilling operation, crucial for guiding the drill string.

Drill String and Collars: A series of pipes and heavy weights that provide pressure for drilling.

Drill Bits: Designed according to the geological structure, these vary from diamond-tipped bits for hard rock to softer bits for soil.

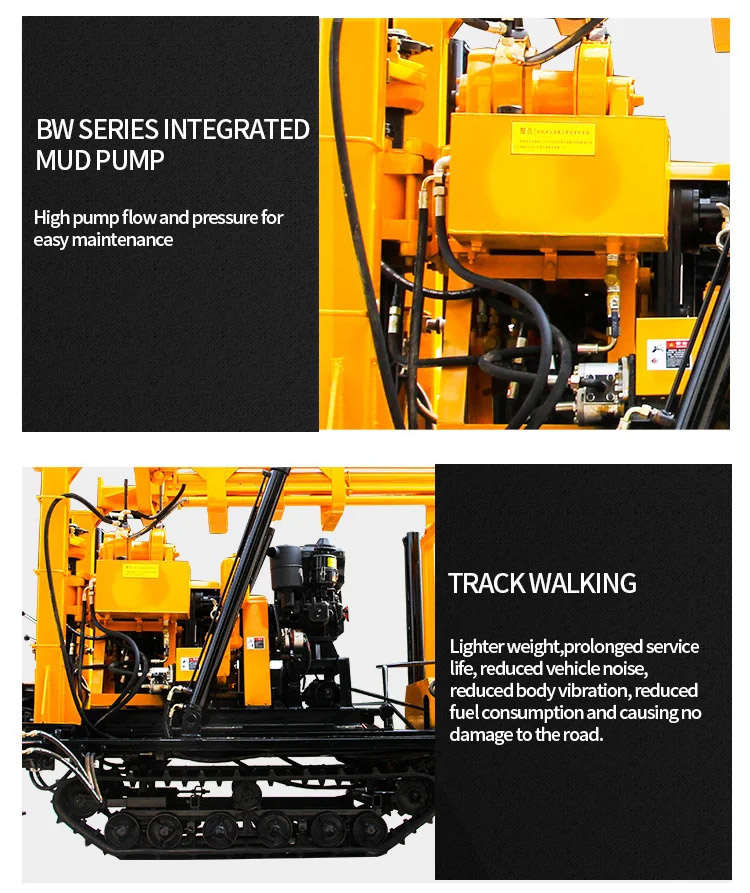

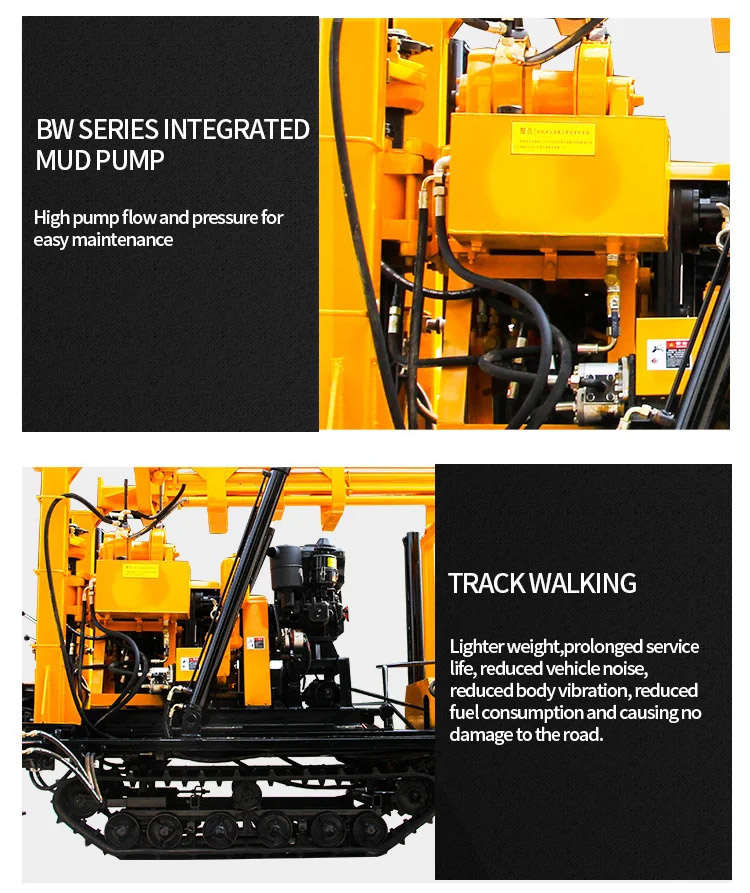

Mud Systems: Critical for lubricating the drill bit, stabilizing the well walls, and removing cuttings.

Power Unit: Often diesel engines, though some rigs use electric or hybrid systems.

Drilling Techniques

Rotary Drilling: The most common method, involving a rotating drill bit and the circulation of drilling mud.

Percussion Drilling: Uses a hammering action to break the earth, suitable for rocky terrains.

Directional Drilling: For accessing water resources under obstacles or in environmentally sensitive areas.

Applications

Rural and Urban Water Supply: Critical for providing water in both urban and rural settings.

Irrigation Systems: Essential for agriculture, especially in arid regions.

Industrial Processes: Many industries rely on large quantities of water sourced through these rigs.

Safety and Sustainability

Safety Standards: Rigorous standards and protocols are necessary to ensure the safety of operators.

Environmental Considerations: Measures to minimize the impact on the local ecosystem, including careful management of drilling by-products.

Technological Innovations

Advancements in automation, telemetry, and environmental safeguards have significantly improved the efficiency and reduced the environmental impact of these rigs.

In summary, water well drilling rigs are complex, highly specialized machines designed for accessing one of our most vital natural resources: water. They represent a convergence of engineering, environmental science, and practical know-how, playing a pivotal role in sustaining human activities across the globe.

标签

获取最新价格?我们会尽快回复(12小时内)