durable FYL-600 Walk-behind Single Drum Roller

The machine is typically powered by a small, yet robust internal combustion engine, although newer models may feature electric motors. The power source drives both the drum and the machine itself, enabling it to move forward or backward.

- FYL-600

- ZHUOXIN

- Walk-behind Single Drum Roller

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Maintenance is straightforward, typically involving regular engine checks, drum cleaning, and ensuring the vibration mechanism is functioning correctly. Operation usually requires minimal training, with intuitive controls for speed, direction, and vibration.

Description

In the world of construction and roadwork, efficiency and precision are paramount. The compact hand-held single-drum roller emerges as an essential tool in this context, especially for small-scale projects and confined spaces.

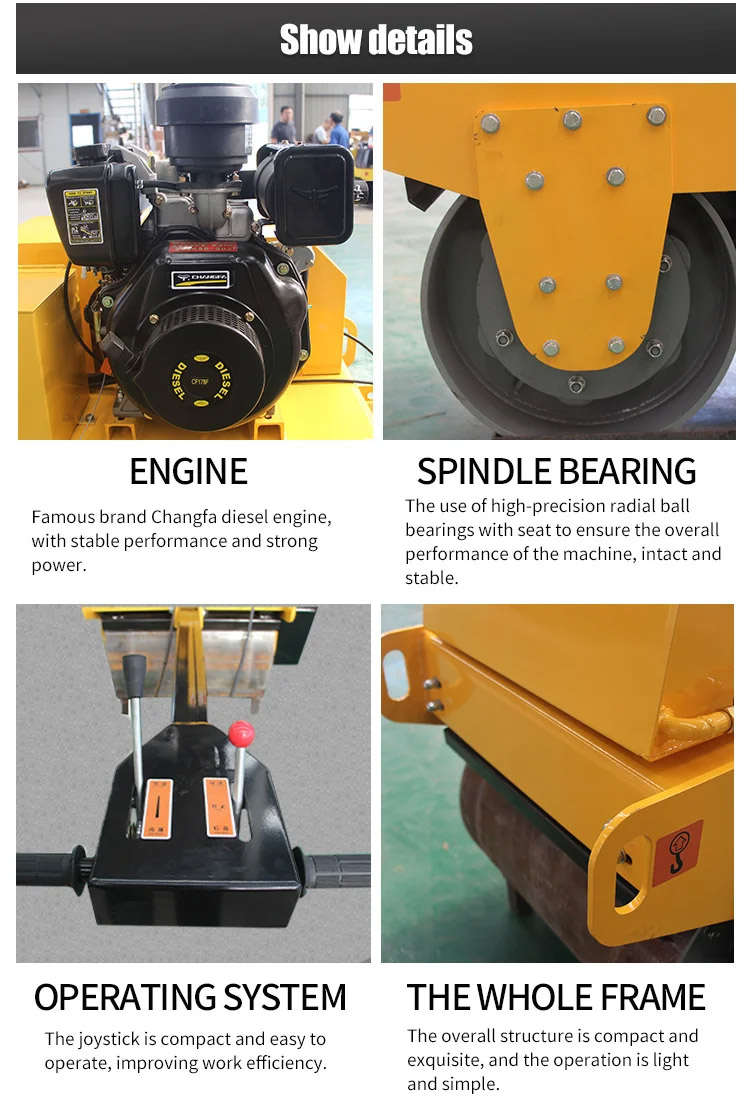

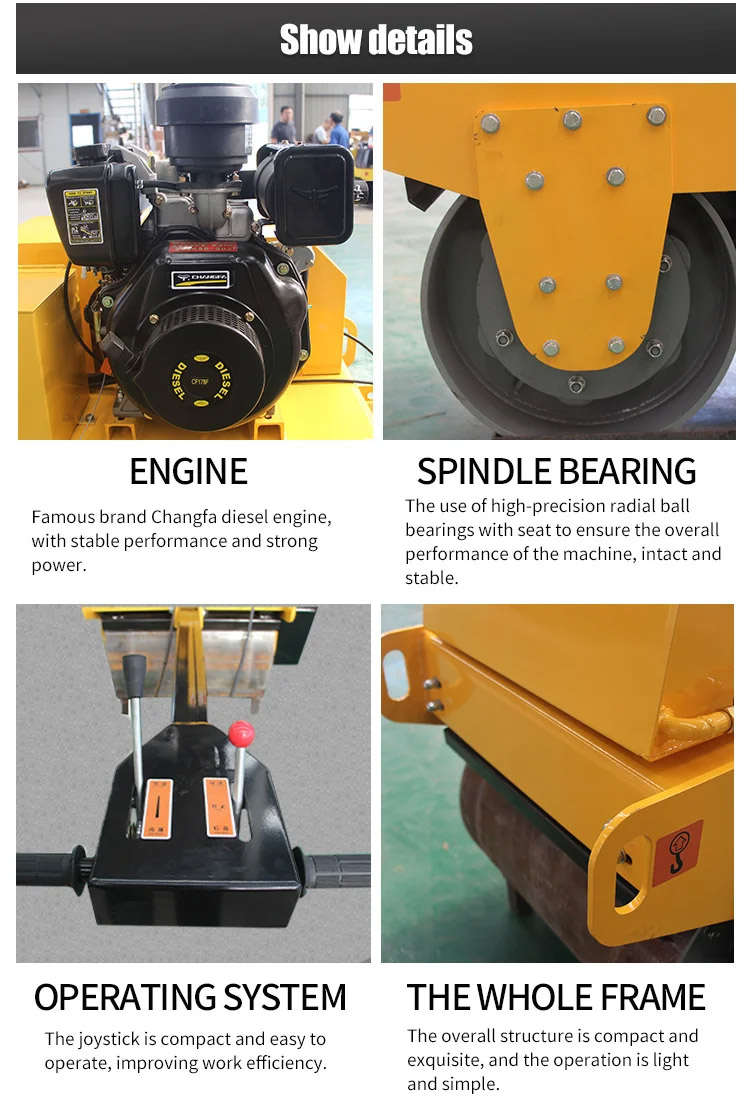

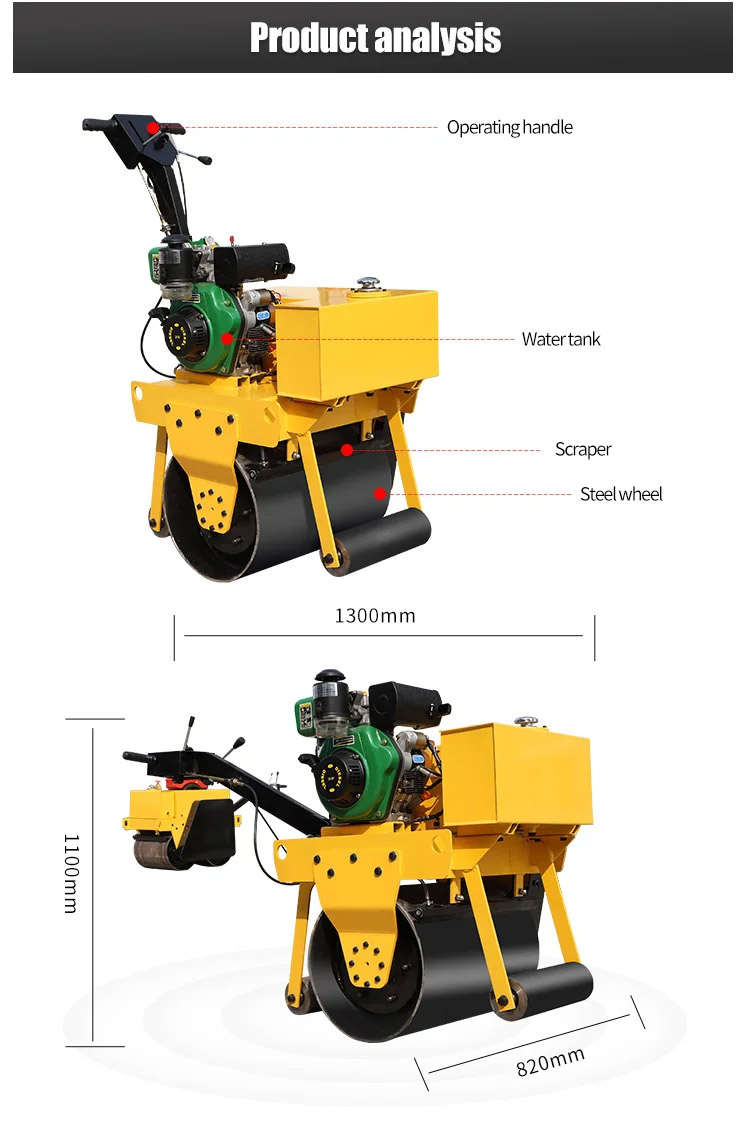

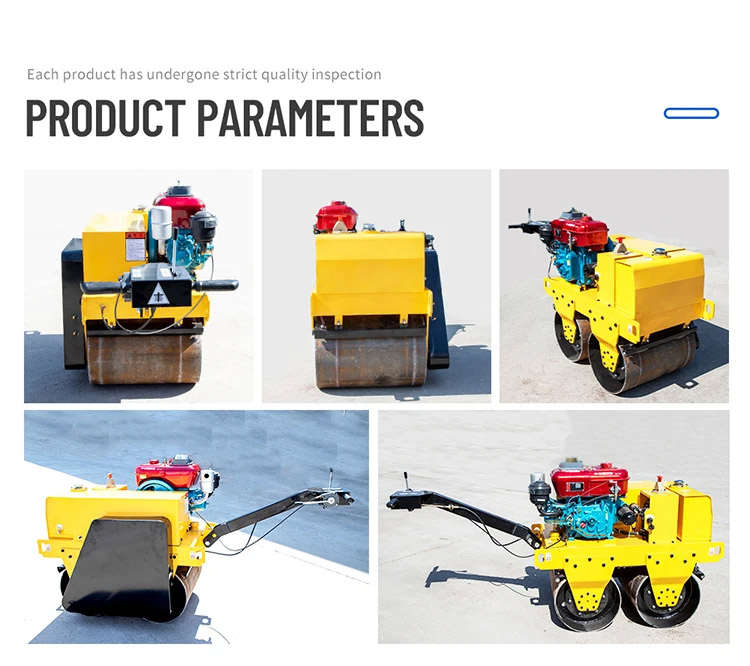

Design and Features

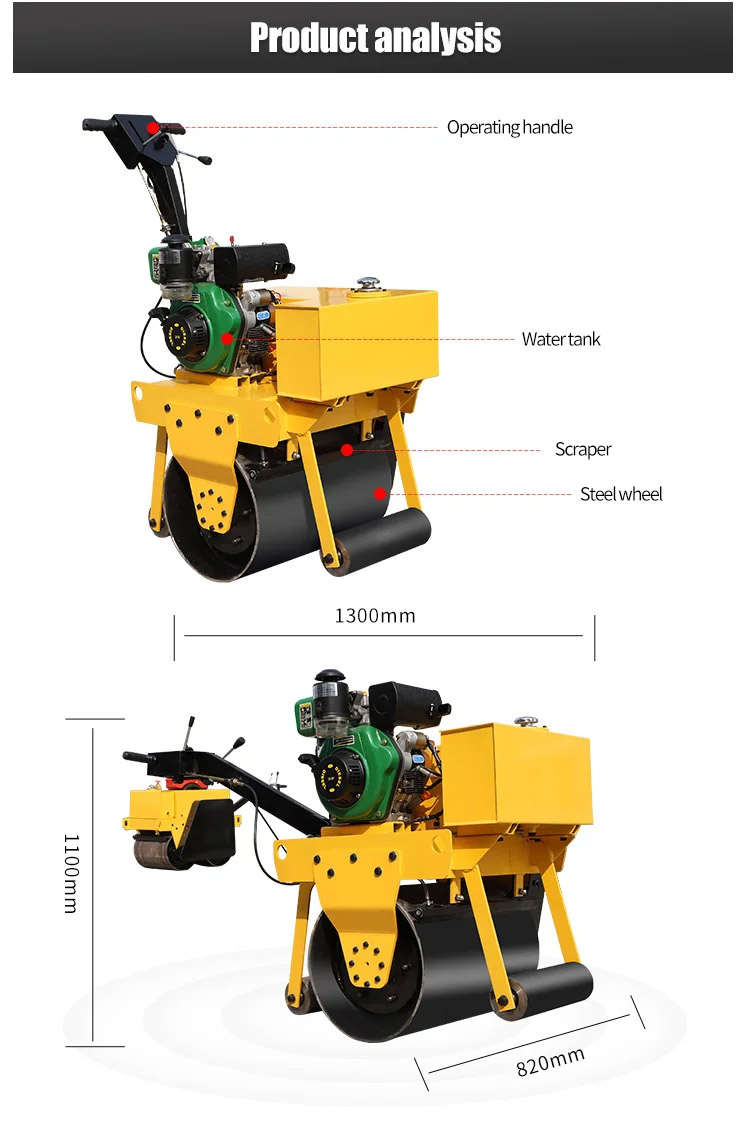

The single-drum roller, as its name suggests, features a single large drum in the front and smaller wheels at the rear. This design facilitates easy maneuverability and focused pressure application, making it ideal for compacting soil, gravel, concrete, or asphalt in narrow spaces.

The machine is typically powered by a small, yet robust internal combustion engine, although newer models may feature electric motors. The power source drives both the drum and the machine itself, enabling it to move forward or backward.

Key features include:

Compact Size: The small size allows access to tight areas, such as sidewalks, driveways, and landscaping projects.

Vibration Mechanism: The drum includes a vibrating function, which enhances compaction efficiency.

Ergonomic Handle: An adjustable handle improves operator comfort and control.

Water Tank: Some models include a water tank for asphalt compaction, helping to prevent the material from sticking to the drum.

Safety Features: These might include emergency stop buttons, protective covers for moving parts, and noise reduction systems.

Applications

This equipment is particularly useful for:

Compacting soil in trenches or for foundation work.

Leveling ground for landscaping or small construction projects.

Compacting asphalt for patching potholes or laying small paths.

Maintenance and Operation

Maintenance is straightforward, typically involving regular engine checks, drum cleaning, and ensuring the vibration mechanism is functioning correctly. Operation usually requires minimal training, with intuitive controls for speed, direction, and vibration.

Conclusion

The hand-held single-drum roller is a versatile and efficient piece of equipment for small-scale construction and landscaping work. Its ease of use, combined with effective compaction capabilities, makes it a valuable tool in any construction toolkit.

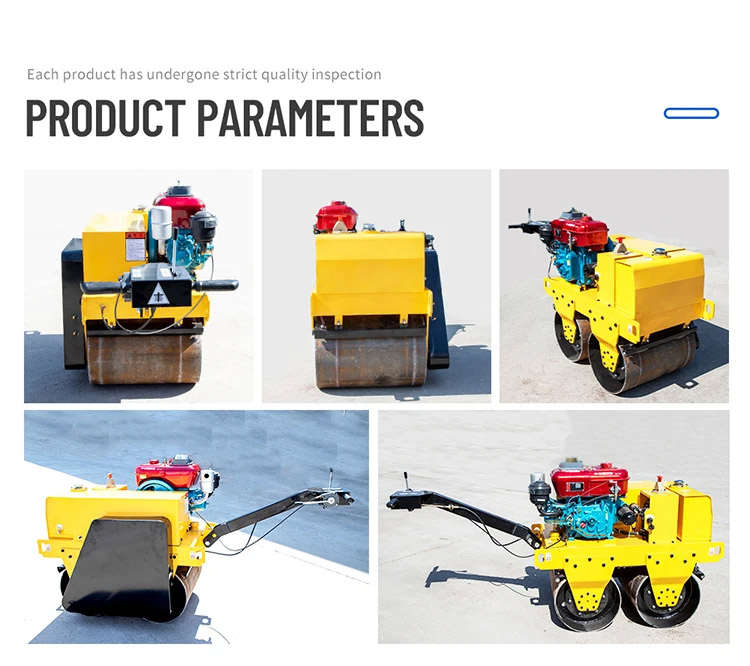

The hand-held single-drum roller, a marvel in the field of small-scale construction and landscaping, has revolutionized how professionals approach compacting tasks in limited space environments. This equipment is designed to offer both precision and efficiency, making it indispensable for a variety of projects.

Unique Design Characteristics

The roller features a distinctive design with a singular large drum at the front and smaller wheels at the back. This configuration allows for targeted compaction force, essential for materials such as soil, asphalt, and concrete, especially in tight spaces and intricate designs.

It typically runs on a potent internal combustion engine, but newer models may feature electric motors, aligning with eco-friendly initiatives. The engine powers both the drum's rotation and the machine's locomotion, providing necessary versatility.

Design and Features

The single-drum roller, as its name suggests, features a single large drum in the front and smaller wheels at the rear. This design facilitates easy maneuverability and focused pressure application, making it ideal for compacting soil, gravel, concrete, or asphalt in narrow spaces.

The machine is typically powered by a small, yet robust internal combustion engine, although newer models may feature electric motors. The power source drives both the drum and the machine itself, enabling it to move forward or backward.

Key features include:

Compact Size: The small size allows access to tight areas, such as sidewalks, driveways, and landscaping projects.

Vibration Mechanism: The drum includes a vibrating function, which enhances compaction efficiency.

Ergonomic Handle: An adjustable handle improves operator comfort and control.

Water Tank: Some models include a water tank for asphalt compaction, helping to prevent the material from sticking to the drum.

Safety Features: These might include emergency stop buttons, protective covers for moving parts, and noise reduction systems.

Applications

This equipment is particularly useful for:

Compacting soil in trenches or for foundation work.

Leveling ground for landscaping or small construction projects.

Compacting asphalt for patching potholes or laying small paths.

Maintenance and Operation

Maintenance is straightforward, typically involving regular engine checks, drum cleaning, and ensuring the vibration mechanism is functioning correctly. Operation usually requires minimal training, with intuitive controls for speed, direction, and vibration.

Conclusion

The hand-held single-drum roller is a versatile and efficient piece of equipment for small-scale construction and landscaping work. Its ease of use, combined with effective compaction capabilities, makes it a valuable tool in any construction toolkit.

The hand-held single-drum roller, a marvel in the field of small-scale construction and landscaping, has revolutionized how professionals approach compacting tasks in limited space environments. This equipment is designed to offer both precision and efficiency, making it indispensable for a variety of projects.

Unique Design Characteristics

The roller features a distinctive design with a singular large drum at the front and smaller wheels at the back. This configuration allows for targeted compaction force, essential for materials such as soil, asphalt, and concrete, especially in tight spaces and intricate designs.

It typically runs on a potent internal combustion engine, but newer models may feature electric motors, aligning with eco-friendly initiatives. The engine powers both the drum's rotation and the machine's locomotion, providing necessary versatility.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)