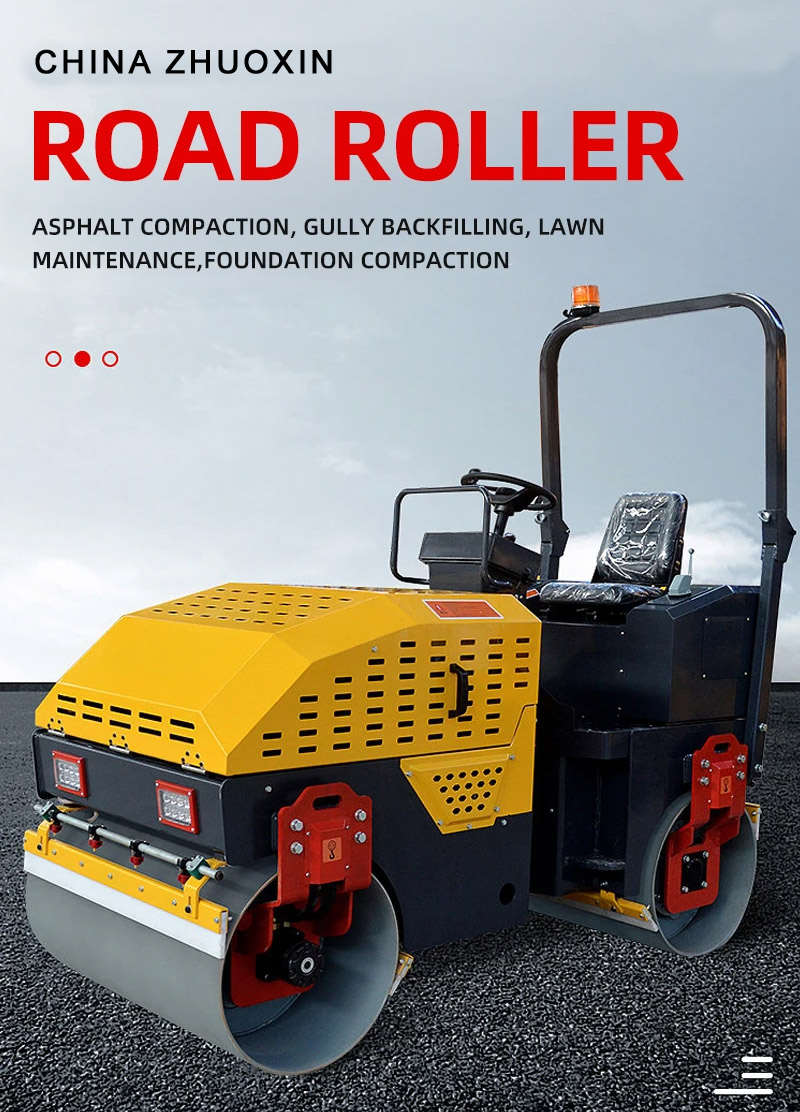

2T Ride-on Road Roller high-performance

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements.

- 2T

- ZHUOXIN

- Ride-on Road Roller

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Engine: Road rollers are equipped with robust engines that provide the necessary horsepower to propel the machine and operate the roller drum. Diesel engines are commonly employed for their high torque and reliability.

Description

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the longevity and uniformity of road surfaces underscores its indispensability in modern construction and infrastructure development projects.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with robust engines that provide the necessary horsepower to propel the machine and operate the roller drum. Diesel engines are commonly employed for their high torque and reliability.

Cabin: The operator's cabin serves as the command center for the roller. It offers a comfortable seating arrangement, controls for steering, speed adjustment, and drum vibration modulation. Safety features such as roll-over protection structures (ROPS) and seat belts are integral components of the cabin.

Vibratory System: Many modern road rollers feature a vibratory system that allows the roller drum to oscillate or vibrate. This feature significantly enhances compaction efficiency by reducing air voids within the material being compacted.

Water Spray System: To prevent asphalt from sticking to the roller drum and to control dust during soil compaction, road rollers are often equipped with a water spray system that moistens the drum.

Types of Road Rollers:

Various types of road rollers are tailored for specific compaction tasks:

Static Rollers: These rollers feature non-vibrating smooth drums and are ideally suited for applying finishing touches to asphalt surfaces.

Pneumatic Rollers: Equipped with rubber tires, pneumatic rollers excel in sealing and finishing asphalt surfaces.

Sheepsfoot Rollers: These rollers are equipped with padfoot drums featuring protruding lugs, making them exceptional for compacting cohesive soils.

The road roller, often called a compactor or steamroller, stands as a marvel of engineering in the realm of heavy-duty construction machinery. This robust and versatile machine finds its primary use in compacting a wide array of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the durability and smoothness of road surfaces makes it an indispensable asset in contemporary construction and infrastructure development projects.

Key Components:

A typical road roller comprises several key components, each contributing to its efficiency and functionality:

Roller Drum: At the heart of the road roller lies the roller drum, typically crafted from sturdy steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with powerful engines that deliver the necessary horsepower for propelling the machine and operating the roller drum. Diesel engines are often favored for their high torque and reliability.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with robust engines that provide the necessary horsepower to propel the machine and operate the roller drum. Diesel engines are commonly employed for their high torque and reliability.

Cabin: The operator's cabin serves as the command center for the roller. It offers a comfortable seating arrangement, controls for steering, speed adjustment, and drum vibration modulation. Safety features such as roll-over protection structures (ROPS) and seat belts are integral components of the cabin.

Vibratory System: Many modern road rollers feature a vibratory system that allows the roller drum to oscillate or vibrate. This feature significantly enhances compaction efficiency by reducing air voids within the material being compacted.

Water Spray System: To prevent asphalt from sticking to the roller drum and to control dust during soil compaction, road rollers are often equipped with a water spray system that moistens the drum.

Types of Road Rollers:

Various types of road rollers are tailored for specific compaction tasks:

Static Rollers: These rollers feature non-vibrating smooth drums and are ideally suited for applying finishing touches to asphalt surfaces.

Pneumatic Rollers: Equipped with rubber tires, pneumatic rollers excel in sealing and finishing asphalt surfaces.

Sheepsfoot Rollers: These rollers are equipped with padfoot drums featuring protruding lugs, making them exceptional for compacting cohesive soils.

The road roller, often called a compactor or steamroller, stands as a marvel of engineering in the realm of heavy-duty construction machinery. This robust and versatile machine finds its primary use in compacting a wide array of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the durability and smoothness of road surfaces makes it an indispensable asset in contemporary construction and infrastructure development projects.

Key Components:

A typical road roller comprises several key components, each contributing to its efficiency and functionality:

Roller Drum: At the heart of the road roller lies the roller drum, typically crafted from sturdy steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with powerful engines that deliver the necessary horsepower for propelling the machine and operating the roller drum. Diesel engines are often favored for their high torque and reliability.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)