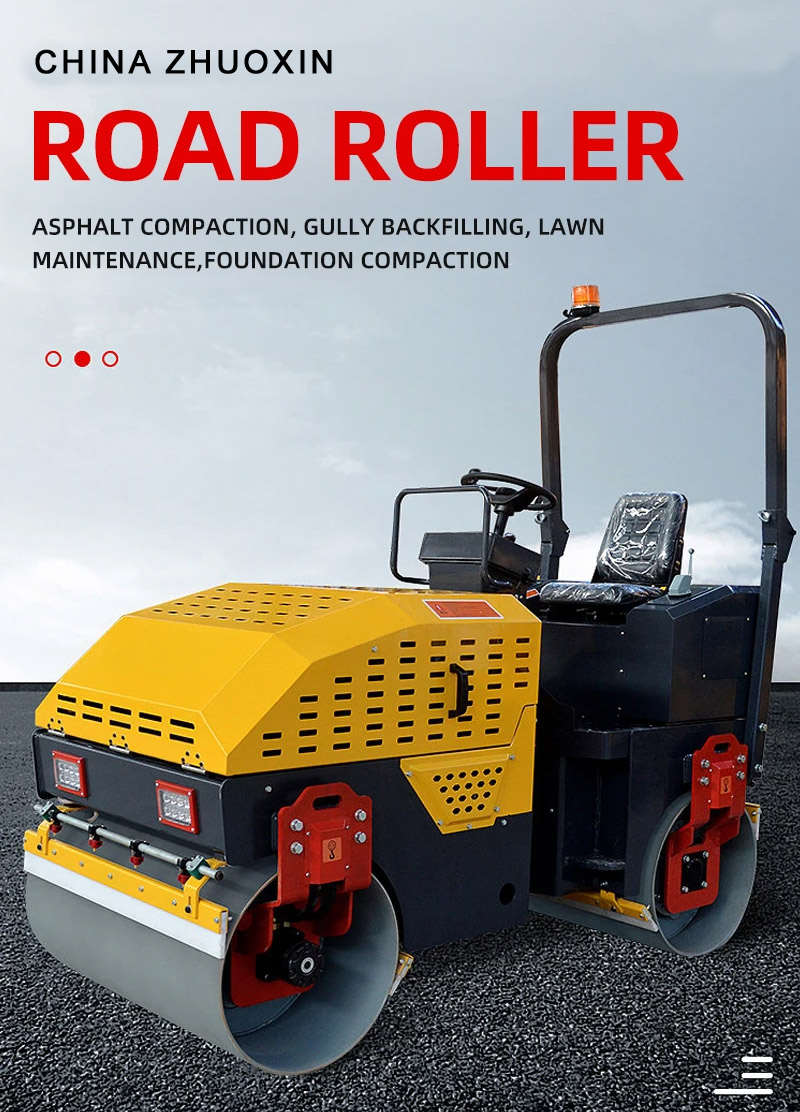

wholesale AL850 Ride-on Road Roller sale

The ride on double drum roller compactor is small-size vibratory roller, applied to mending and maintaining various roads, expressway shoulder, roadside walk, parking area, sports ground and garden lawn. They are especially suited for compaction of narrow areas as pipeline channel and drainage trench etc.

- ZHUOXIN

- Ride-on Road Roller

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Diesel Ride on Vibratory Soil Compaction Equipment Applications: Used for compaction of asphalt surface, compaction of gravel, sand and other projects.

Description

850 Ride On Vibration Compactor Roller

Diesel Ride on Vibratory Soil Compaction Equipment Applications: Used for compaction of asphalt surface, compaction of gravel, sand and other projects.

Product Introduction

Diesel Ride on Vibratory Soil Compaction Equipment

Applications:

Used for compaction of asphalt surface, compaction of gravel, sand and other projects.

The ride on double drum roller compactor is small-size vibratory roller, applied to mending and maintaining various roads, expressway shoulder, roadside walk, parking area, sports ground and garden lawn. They are especially suited for compaction of narrow areas as pipeline channel and drainage trench etc.

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the longevity and uniformity of road surfaces underscores its indispensability in modern construction and infrastructure development projects.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with robust engines that provide the necessary horsepower to propel the machine and operate the roller drum. Diesel engines are commonly employed for their high torque and reliability.

Cabin: The operator's cabin serves as the command center for the roller. It offers a comfortable seating arrangement, controls for steering, speed adjustment, and drum vibration modulation. Safety features such as roll-over protection structures (ROPS) and seat belts are integral components of the cabin.

Operation:

Operating a road roller requires skilled personnel well-versed in the principles of compaction. The operator maneuvers the machine across the designated area, adjusting the drum's vibration frequency and amplitude as necessary. The roller's sheer weight, combined with the vibrating action, compresses the material, diminishing voids and ensuring a solid, even surface.

Applications:

Road rollers find indispensable applications in a multitude of construction and maintenance projects, including:

Road construction and repair

Airport runway construction

Building foundation preparation

Landfill compaction

Trench and pipeline backfill compaction

Conclusion:

The road roller stands as an awe-inspiring feat of engineering in the domain of construction and infrastructure development. Its exceptional capacity to efficiently compact diverse materials underscores its role in ensuring the longevity and safety of roads and other critical structures. With continued technological advancements, road rollers evolve to be more efficient and environmentally friendly, all while preserving their fundamental role in crafting smoother and safer surfaces for all to traverse.

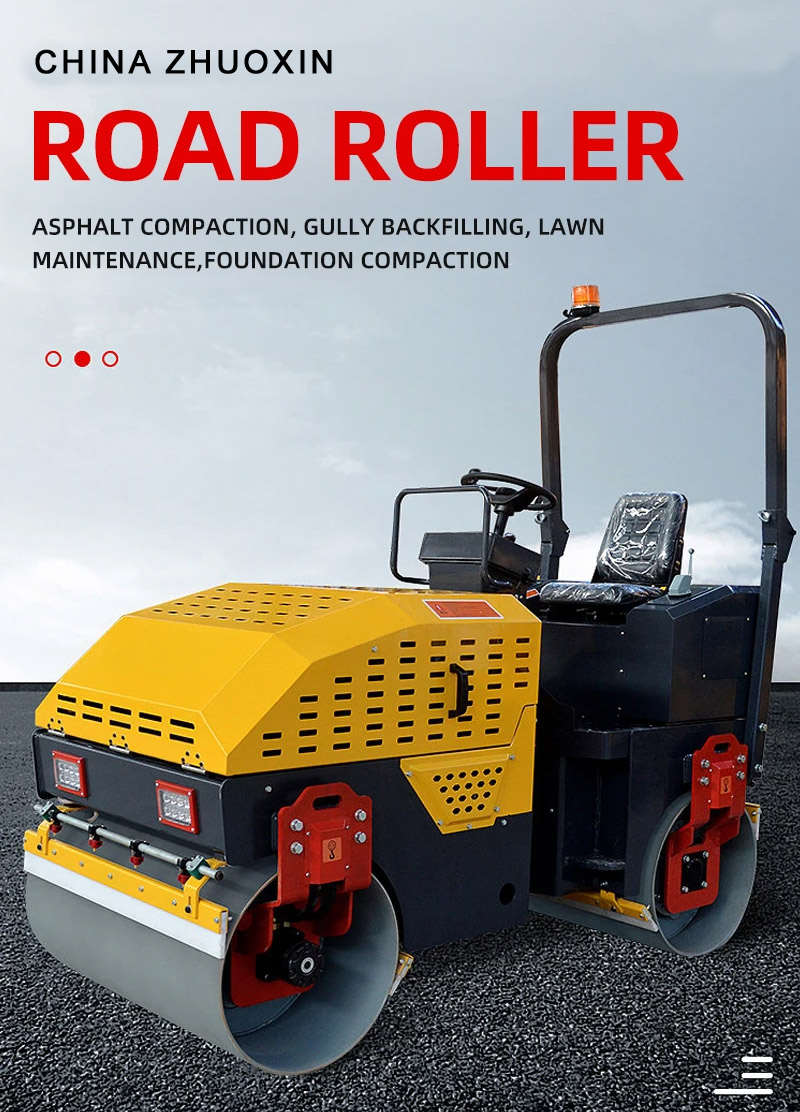

Diesel Ride on Vibratory Soil Compaction Equipment Applications: Used for compaction of asphalt surface, compaction of gravel, sand and other projects.

Product Introduction

Diesel Ride on Vibratory Soil Compaction Equipment

Applications:

Used for compaction of asphalt surface, compaction of gravel, sand and other projects.

The ride on double drum roller compactor is small-size vibratory roller, applied to mending and maintaining various roads, expressway shoulder, roadside walk, parking area, sports ground and garden lawn. They are especially suited for compaction of narrow areas as pipeline channel and drainage trench etc.

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the longevity and uniformity of road surfaces underscores its indispensability in modern construction and infrastructure development projects.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Engine: Road rollers are equipped with robust engines that provide the necessary horsepower to propel the machine and operate the roller drum. Diesel engines are commonly employed for their high torque and reliability.

Cabin: The operator's cabin serves as the command center for the roller. It offers a comfortable seating arrangement, controls for steering, speed adjustment, and drum vibration modulation. Safety features such as roll-over protection structures (ROPS) and seat belts are integral components of the cabin.

Operation:

Operating a road roller requires skilled personnel well-versed in the principles of compaction. The operator maneuvers the machine across the designated area, adjusting the drum's vibration frequency and amplitude as necessary. The roller's sheer weight, combined with the vibrating action, compresses the material, diminishing voids and ensuring a solid, even surface.

Applications:

Road rollers find indispensable applications in a multitude of construction and maintenance projects, including:

Road construction and repair

Airport runway construction

Building foundation preparation

Landfill compaction

Trench and pipeline backfill compaction

Conclusion:

The road roller stands as an awe-inspiring feat of engineering in the domain of construction and infrastructure development. Its exceptional capacity to efficiently compact diverse materials underscores its role in ensuring the longevity and safety of roads and other critical structures. With continued technological advancements, road rollers evolve to be more efficient and environmentally friendly, all while preserving their fundamental role in crafting smoother and safer surfaces for all to traverse.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)