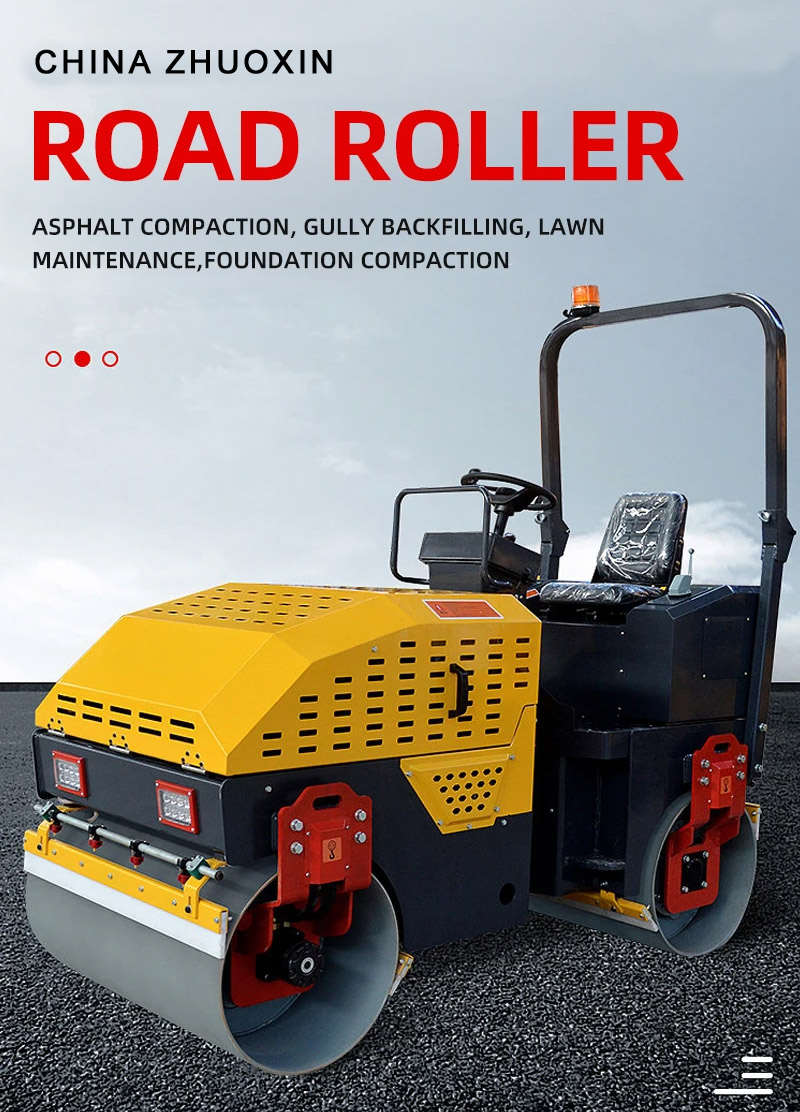

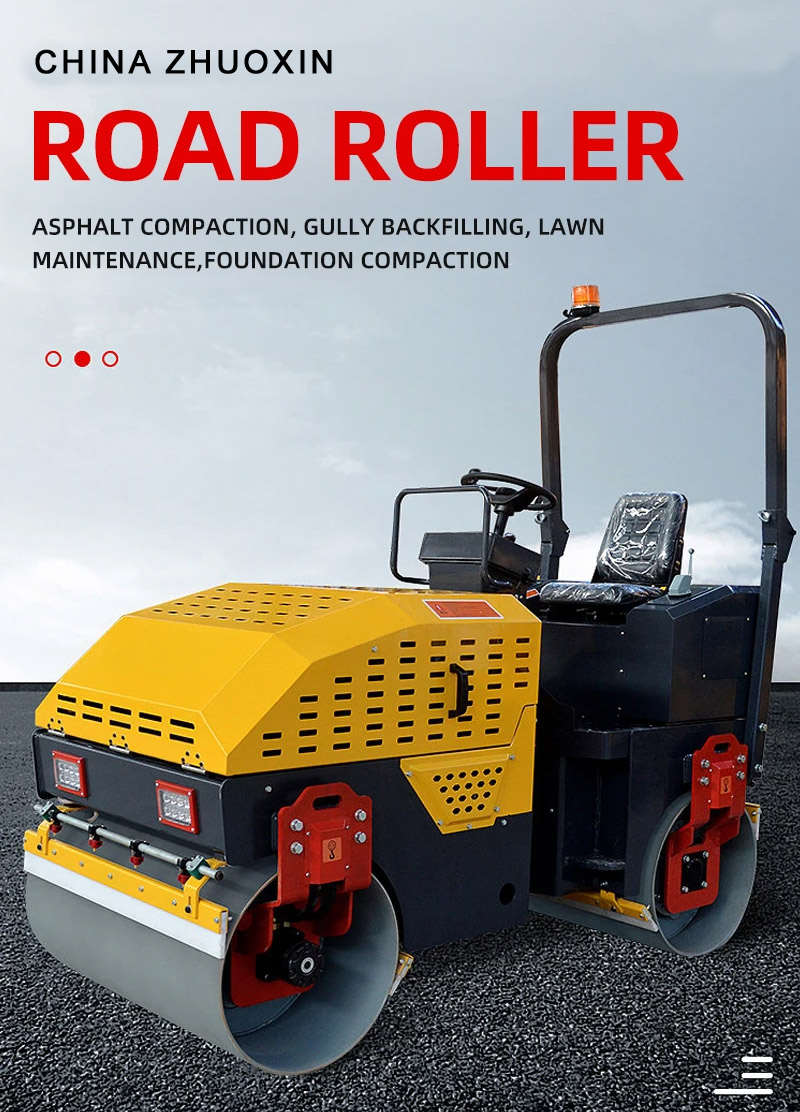

AT-850 Walk-behind Double Drum Roller durable

Water Spray System: To prevent asphalt from sticking to the roller drum and to control dust during soil compaction, road rollers are often equipped with a water spray system that wets the drum.

- AT-850

- ZHUOXIN

- Walk-behind Double Drum Roller

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Vibratory System: Many modern road rollers are equipped with a vibratory system that allows the roller drum to oscillate or vibrate. This feature enhances compaction efficiency by reducing air voids in the material being compacted.

Description

The road roller, often referred to as a compactor or steamroller, is an essential heavy-duty construction machine used for the compaction of various types of surfaces, primarily roads and pavements. This powerful piece of equipment plays a crucial role in ensuring the durability and smoothness of road surfaces, making it a vital component of modern construction and infrastructure development projects.

Key Components:

A typical road roller consists of several key components, each contributing to its efficiency and functionality:

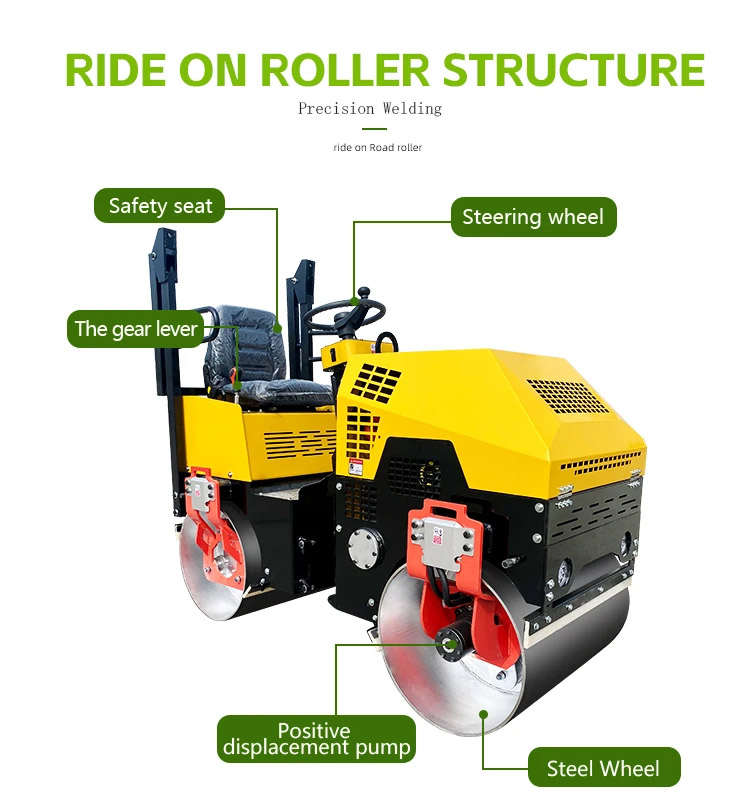

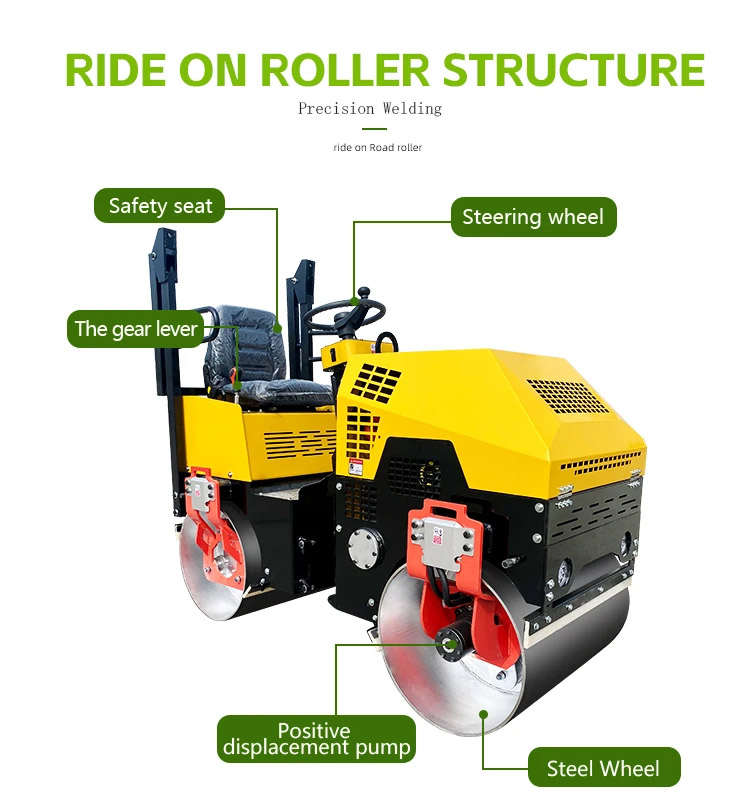

Roller Drum: The heart of the road roller is the roller drum, which is usually made of steel. It is the part that comes into direct contact with the surface being compacted. The design and size of the roller drum can vary, with some rollers having smooth drums for asphalt compaction and others equipped with padfoot drums for soil compaction.

Engine: Road rollers are equipped with powerful engines that provide the necessary horsepower to propel the machine and operate the roller drum. These engines are often diesel-powered for greater torque and reliability.

Cabin: The operator's cabin is where the roller is controlled. It features a comfortable seat, controls for steering, speed, and drum vibration, as well as safety features such as roll-over protection structures (ROPS) and seat belts.

Vibratory System: Many modern road rollers are equipped with a vibratory system that allows the roller drum to oscillate or vibrate. This feature enhances compaction efficiency by reducing air voids in the material being compacted.

Water Spray System: To prevent asphalt from sticking to the roller drum and to control dust during soil compaction, road rollers are often equipped with a water spray system that wets the drum.

Types of Road Rollers:

There are several types of road rollers, each designed for specific compaction tasks:

Static Rollers: These rollers have non-vibrating smooth drums and are used for finishing touches on asphalt surfaces.

Vibratory Rollers: These rollers have vibrating drums, making them suitable for both asphalt and soil compaction.

Pneumatic Rollers: Equipped with rubber tires, pneumatic rollers are used for sealing and finishing asphalt surfaces.

Sheepsfoot Rollers: These rollers have padfoot drums with protruding lugs and are excellent for compacting cohesive soils.

Operation:

Operating a road roller requires skilled personnel who understand the principles of compaction. The operator maneuvers the machine over the designated area, adjusting the drum's vibration frequency and amplitude as needed. The roller's weight, combined with the vibrating action, compresses the material, reducing voids and ensuring a solid, even surface.

Landfill compaction

Trench and pipeline backfill compaction

Conclusion:

The road roller is a formidable machine in the world of construction and infrastructure development. Its ability to compact various materials efficiently ensures the longevity and safety of roads and other structures. With advancements in technology, road rollers continue to evolve, becoming more efficient and environmentally friendly while maintaining their essential role in creating smoother and safer surfaces for all of us to travel on.

Roller Drum: The core of the road roller is the roller drum, typically constructed from steel. It is the part that comes into direct contact with the surface being compacted. The design and size of the roller drum can vary, with some rollers having smooth drums for asphalt compaction and others featuring padfoot drums for soil compaction.

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the longevity and uniformity of road surfaces underscores its indispensability in modern construction and infrastructure development projects.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Key Components:

A typical road roller consists of several key components, each contributing to its efficiency and functionality:

Roller Drum: The heart of the road roller is the roller drum, which is usually made of steel. It is the part that comes into direct contact with the surface being compacted. The design and size of the roller drum can vary, with some rollers having smooth drums for asphalt compaction and others equipped with padfoot drums for soil compaction.

Engine: Road rollers are equipped with powerful engines that provide the necessary horsepower to propel the machine and operate the roller drum. These engines are often diesel-powered for greater torque and reliability.

Cabin: The operator's cabin is where the roller is controlled. It features a comfortable seat, controls for steering, speed, and drum vibration, as well as safety features such as roll-over protection structures (ROPS) and seat belts.

Vibratory System: Many modern road rollers are equipped with a vibratory system that allows the roller drum to oscillate or vibrate. This feature enhances compaction efficiency by reducing air voids in the material being compacted.

Water Spray System: To prevent asphalt from sticking to the roller drum and to control dust during soil compaction, road rollers are often equipped with a water spray system that wets the drum.

Types of Road Rollers:

There are several types of road rollers, each designed for specific compaction tasks:

Static Rollers: These rollers have non-vibrating smooth drums and are used for finishing touches on asphalt surfaces.

Vibratory Rollers: These rollers have vibrating drums, making them suitable for both asphalt and soil compaction.

Pneumatic Rollers: Equipped with rubber tires, pneumatic rollers are used for sealing and finishing asphalt surfaces.

Sheepsfoot Rollers: These rollers have padfoot drums with protruding lugs and are excellent for compacting cohesive soils.

Operation:

Operating a road roller requires skilled personnel who understand the principles of compaction. The operator maneuvers the machine over the designated area, adjusting the drum's vibration frequency and amplitude as needed. The roller's weight, combined with the vibrating action, compresses the material, reducing voids and ensuring a solid, even surface.

Landfill compaction

Trench and pipeline backfill compaction

Conclusion:

The road roller is a formidable machine in the world of construction and infrastructure development. Its ability to compact various materials efficiently ensures the longevity and safety of roads and other structures. With advancements in technology, road rollers continue to evolve, becoming more efficient and environmentally friendly while maintaining their essential role in creating smoother and safer surfaces for all of us to travel on.

Roller Drum: The core of the road roller is the roller drum, typically constructed from steel. It is the part that comes into direct contact with the surface being compacted. The design and size of the roller drum can vary, with some rollers having smooth drums for asphalt compaction and others featuring padfoot drums for soil compaction.

The road roller, a formidable construction machine, holds a pivotal role in the realm of heavy-duty equipment. Also known as a compactor or steamroller, this robust apparatus finds its primary purpose in compacting a wide range of surfaces, with a primary focus on roads and pavements. Its significance in ensuring the longevity and uniformity of road surfaces underscores its indispensability in modern construction and infrastructure development projects.

Key Components:

A typical road roller boasts several crucial components, each contributing to its efficiency and functionality:

Roller Drum: At the core of the road roller resides the roller drum, typically forged from durable steel. This component makes direct contact with the surface being compacted. The design and dimensions of the roller drum can vary, with some featuring smooth drums for asphalt compaction and others equipped with padfoot drums designed for soil compaction.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)