- Home >

- Product >

- Excavator >

- Wheel excavator >

- View Details

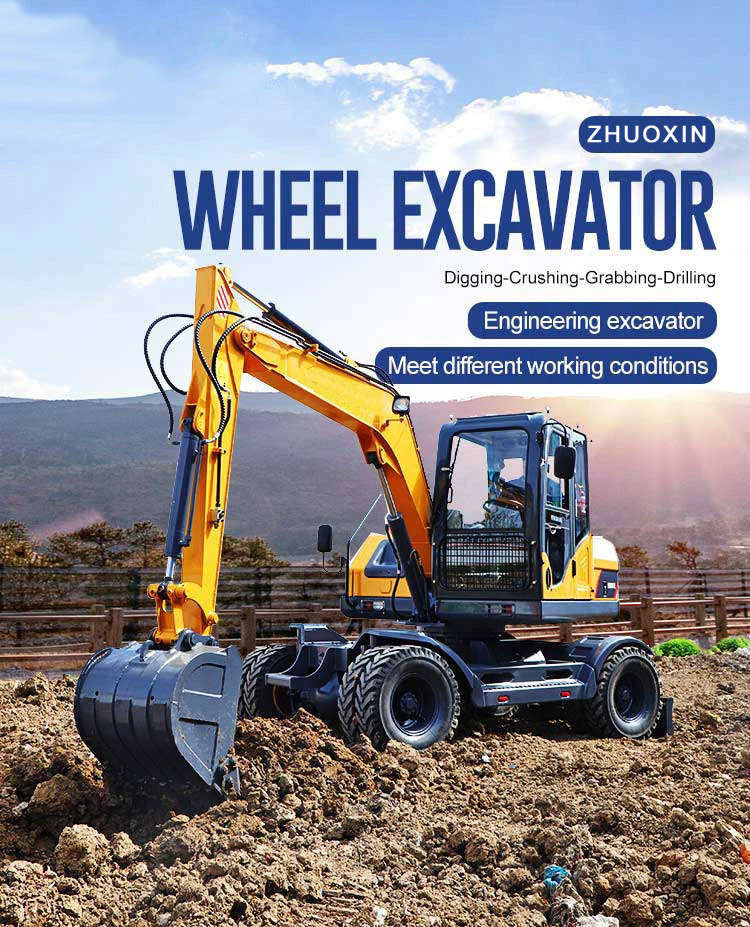

Factory outlet HK-90 Wheel excavator

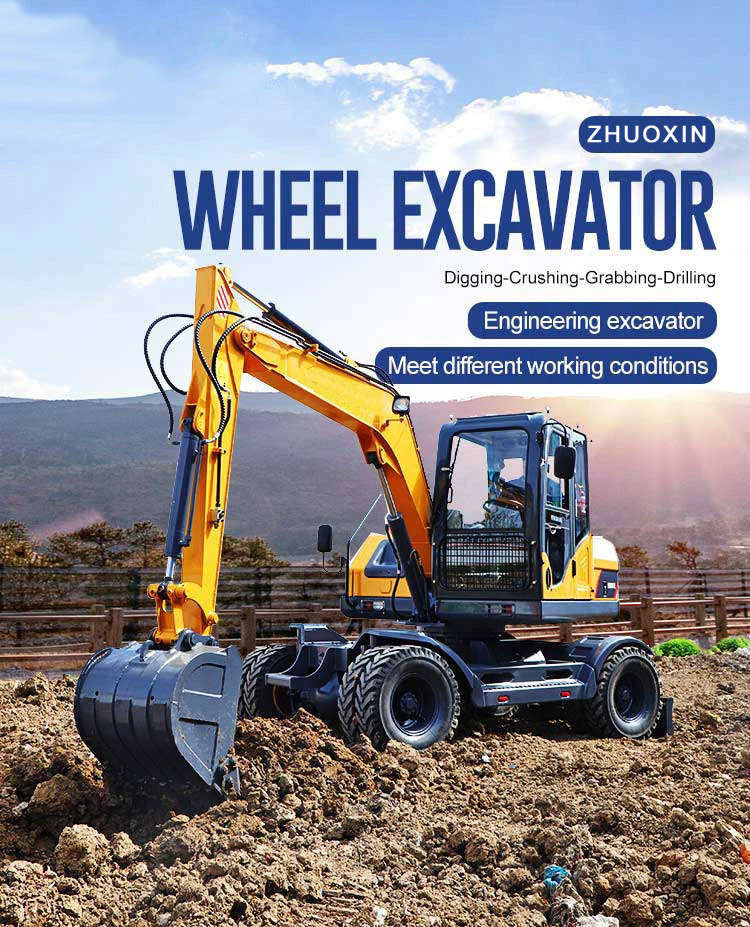

Wheel excavators, a pivotal part of modern construction and excavation projects, stand out for their mobility and versatility. Unlike their tracked counterparts, wheel excavators are equipped with rubber tires, making them ideal for urban or road construction projects where minimal ground disruption and rapid mobility are required.

- HK-90

- ZHUOXIN

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- The most significant advantage of wheel excavators is their ability to move quickly between job sites without the need for additional transportation. This mobility is particularly beneficial in urban construction, where projects are often spread across different locations.

Description

Wheel excavators, a pivotal part of modern construction and excavation projects, stand out for their mobility and versatility. Unlike their tracked counterparts, wheel excavators are equipped with rubber tires, making them ideal for urban or road construction projects where minimal ground disruption and rapid mobility are required.

Design and Features

Mobility

The most significant advantage of wheel excavators is their ability to move quickly between job sites without the need for additional transportation. This mobility is particularly beneficial in urban construction, where projects are often spread across different locations.

Versatility

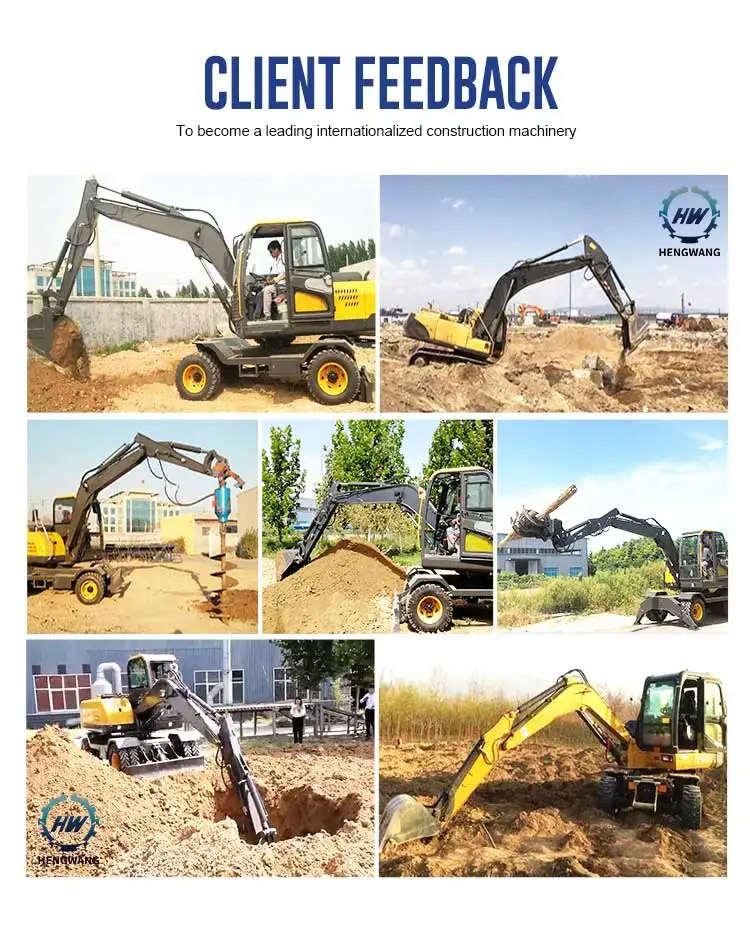

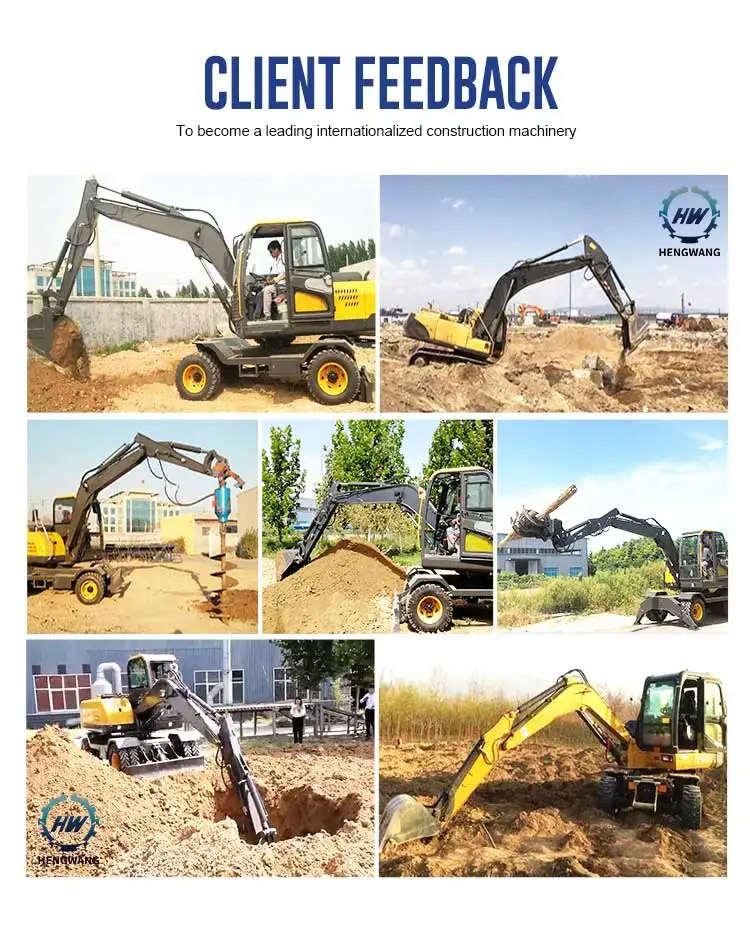

Equipped with various attachments like buckets, hammers, grapples, and augers, wheel excavators can perform a range of tasks including digging, material handling, demolition, and drilling. Their hydraulic systems are designed for high-efficiency and precision, making them suitable for complex tasks.

Stability and Weight Distribution

Wheel excavators are designed with advanced weight distribution and stabilization systems. Outriggers and blade stabilizers can be deployed to provide additional support during operation, enhancing safety and efficiency.

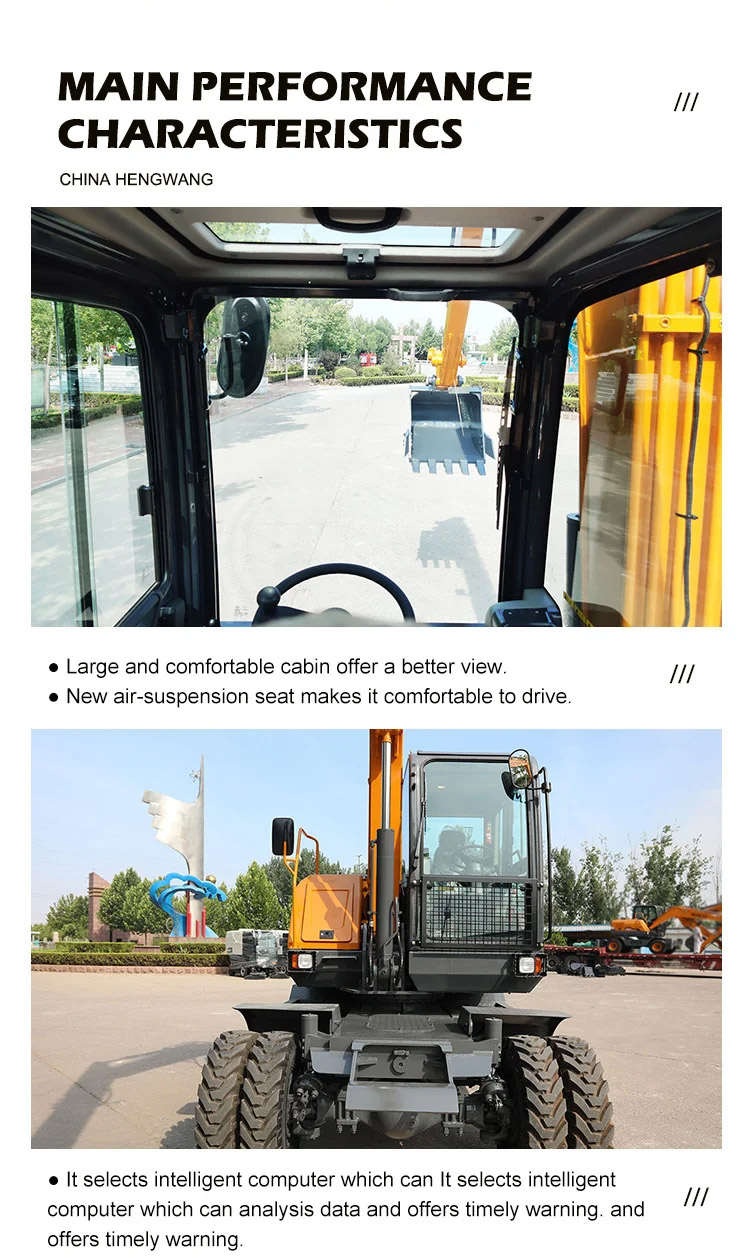

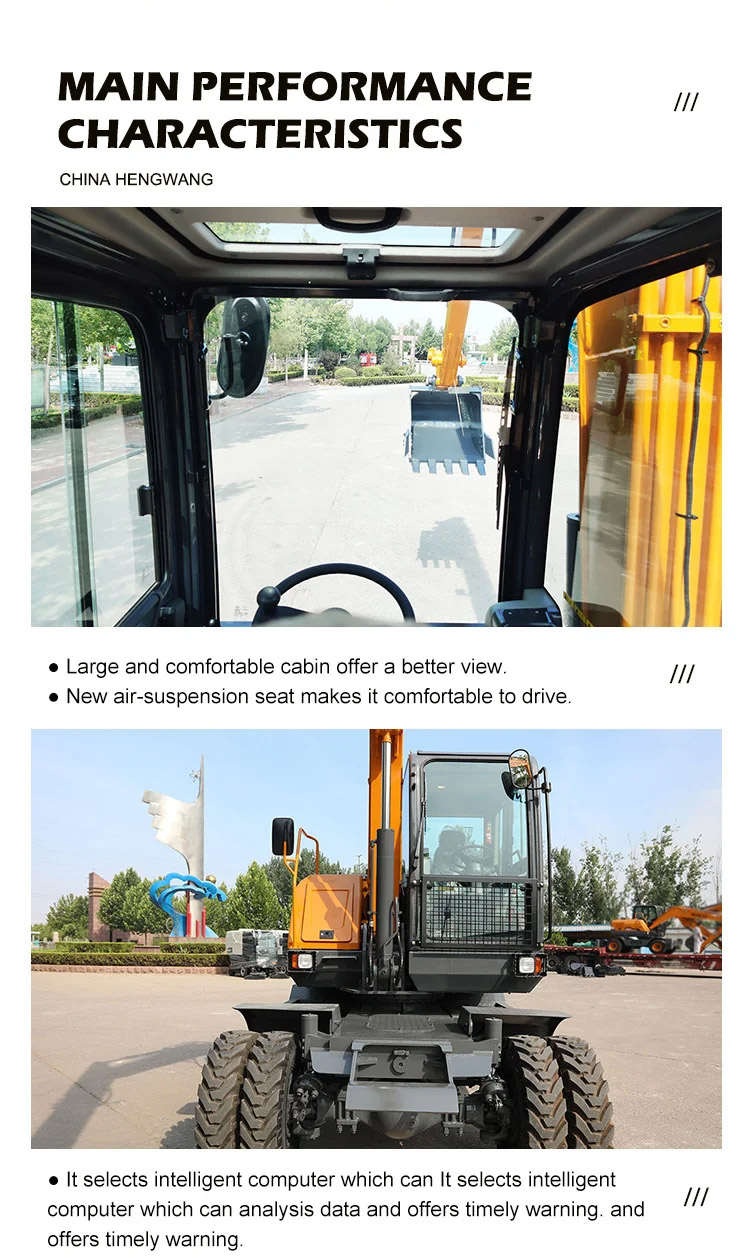

Cabin and Controls

Modern wheel excavators feature ergonomic cabins with advanced controls for operator comfort and efficiency. Features often include adjustable seats, climate control, and intuitive control panels with digital displays.

Urban construction and roadworks for their ability to minimize ground damage.

Utility works like cable or pipe laying due to their precision and mobility.

Landscaping and agricultural tasks for their adaptability in different terrains.

Demolition projects in urban settings where space is limited.

Maintenance and Safety

Regular maintenance is crucial for the longevity and safe operation of wheel excavators. This includes routine checks of the hydraulic system, tires, and attachments. Safety measures like operator training, adherence to operational guidelines, and regular inspections are essential.

Conclusion

Wheel excavators represent a blend of mobility, versatility, and efficiency. Their adaptability to various terrains and tasks makes them an invaluable asset in the construction and excavation industries. As technology advances, we can anticipate even more sophisticated designs enhancing their performance and environmental impact.

Wheel excavators, with their rubber-tire mobility, are able to traverse roads and urban landscapes with ease, reducing the need for transportation via trailers. This capability is especially valuable in projects that require movement across multiple sites.

Wheeled excavators stand as a testament to innovation in the construction industry. These machines, set on durable rubber tires, offer unparalleled mobility and efficiency on various terrains, especially in settings where minimizing surface damage is crucial.

Unique Attributes

Rubber Tire Mobility: The defining trait of wheeled excavators is their rubber tires, which provide significant advantages in terms of speed and maneuverability on hard surfaces, distinguishing them from their tracked counterparts.

High-Speed Transit: These excavators can swiftly move from one site to another without requiring additional transport, significantly reducing downtime and enhancing productivity.

Urban Environment Adaptability: Their design is particularly beneficial in urban and roadside construction projects where preserving the integrity of paved surfaces is paramount.

Versatile Functionality

Diverse Applications: Wheeled excavators are renowned for their versatility, capable of performing a range of tasks such as digging, grading, lifting, and even demolition, with various attachments.

Reduced Infrastructure Impact: Their less abrasive interaction with roads and pavements makes them ideal for work in developed areas, minimizing the need for post-construction road repairs.

Design and Features

Mobility

The most significant advantage of wheel excavators is their ability to move quickly between job sites without the need for additional transportation. This mobility is particularly beneficial in urban construction, where projects are often spread across different locations.

Versatility

Equipped with various attachments like buckets, hammers, grapples, and augers, wheel excavators can perform a range of tasks including digging, material handling, demolition, and drilling. Their hydraulic systems are designed for high-efficiency and precision, making them suitable for complex tasks.

Stability and Weight Distribution

Wheel excavators are designed with advanced weight distribution and stabilization systems. Outriggers and blade stabilizers can be deployed to provide additional support during operation, enhancing safety and efficiency.

Cabin and Controls

Modern wheel excavators feature ergonomic cabins with advanced controls for operator comfort and efficiency. Features often include adjustable seats, climate control, and intuitive control panels with digital displays.

Urban construction and roadworks for their ability to minimize ground damage.

Utility works like cable or pipe laying due to their precision and mobility.

Landscaping and agricultural tasks for their adaptability in different terrains.

Demolition projects in urban settings where space is limited.

Maintenance and Safety

Regular maintenance is crucial for the longevity and safe operation of wheel excavators. This includes routine checks of the hydraulic system, tires, and attachments. Safety measures like operator training, adherence to operational guidelines, and regular inspections are essential.

Conclusion

Wheel excavators represent a blend of mobility, versatility, and efficiency. Their adaptability to various terrains and tasks makes them an invaluable asset in the construction and excavation industries. As technology advances, we can anticipate even more sophisticated designs enhancing their performance and environmental impact.

Wheel excavators, with their rubber-tire mobility, are able to traverse roads and urban landscapes with ease, reducing the need for transportation via trailers. This capability is especially valuable in projects that require movement across multiple sites.

Wheeled excavators stand as a testament to innovation in the construction industry. These machines, set on durable rubber tires, offer unparalleled mobility and efficiency on various terrains, especially in settings where minimizing surface damage is crucial.

Unique Attributes

Rubber Tire Mobility: The defining trait of wheeled excavators is their rubber tires, which provide significant advantages in terms of speed and maneuverability on hard surfaces, distinguishing them from their tracked counterparts.

High-Speed Transit: These excavators can swiftly move from one site to another without requiring additional transport, significantly reducing downtime and enhancing productivity.

Urban Environment Adaptability: Their design is particularly beneficial in urban and roadside construction projects where preserving the integrity of paved surfaces is paramount.

Versatile Functionality

Diverse Applications: Wheeled excavators are renowned for their versatility, capable of performing a range of tasks such as digging, grading, lifting, and even demolition, with various attachments.

Reduced Infrastructure Impact: Their less abrasive interaction with roads and pavements makes them ideal for work in developed areas, minimizing the need for post-construction road repairs.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)