- Home >

- Product >

- Loaders >

- Wheel loaders >

- View Details

ZX-30 Wheel Loaders factory outlet

Front-Mounted Bucket: The defining feature of wheel loaders is their front-mounted bucket, designed for scooping, lifting, and transporting a diverse range of materials.

- ZX-30

- ZHUOXIN

- Wheel Loaders

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Articulated Steering: Wheel loaders typically feature articulated steering, enabling a tight turning radius, making them exceptionally maneuverable in confined spaces.

Description

Wheel loaders, also known as front-end loaders, stand as stalwart machines in the world of material handling and construction. These versatile heavy-duty vehicles are equipped with a front-mounted bucket, making them indispensable for loading, transporting, and moving various materials efficiently. In this comprehensive guide, we will delve into the features, components, types, and wide-ranging applications of wheel loaders.

Features of Wheel Loaders:

Front-Mounted Bucket: The defining feature of wheel loaders is their front-mounted bucket, designed for scooping, lifting, and transporting a diverse range of materials.

Articulated Steering: Wheel loaders typically feature articulated steering, enabling a tight turning radius, making them exceptionally maneuverable in confined spaces.

Powerful Engine: Equipped with robust engines, wheel loaders deliver the horsepower needed to handle heavy loads and challenging terrains.

Hydraulic Systems: Hydraulic systems control critical loader functions, including raising and lowering the bucket, tilting it, and engaging attachments.

Operator Cabin: Modern wheel loaders are equipped with enclosed, climate-controlled operator cabins, enhancing operator comfort and safety.

Components of a Wheel Loader:

Bucket: The front-mounted bucket is the primary attachment for scooping and carrying materials. Different bucket sizes cater to various tasks.

Boom Arms: Responsible for raising and lowering the bucket, boom arms provide articulation and pivot for versatile loading angles.

Hydraulic System: The hydraulic system powers loader movements, ensuring precise bucket control and articulation.

Engine: A robust engine supplies the necessary horsepower to move heavy loads and operate hydraulic functions.

Transmission: The transmission system manages power distribution to the wheels for efficient movement.

Types of Wheel Loaders:

Compact Wheel Loaders: Smaller and highly maneuverable, these loaders are ideal for tasks in landscaping, agriculture, and light construction.

Standard Wheel Loaders: Versatile in size, standard wheel loaders are used in construction, agriculture, mining, and general material handling.

Large Wheel Loaders: Heavy-duty machines designed for mining, quarrying, and major construction projects, capable of handling substantial loads.

Waste and Recycling Loaders: Customized for waste management and recycling operations, these loaders have specialized attachments for handling refuse.

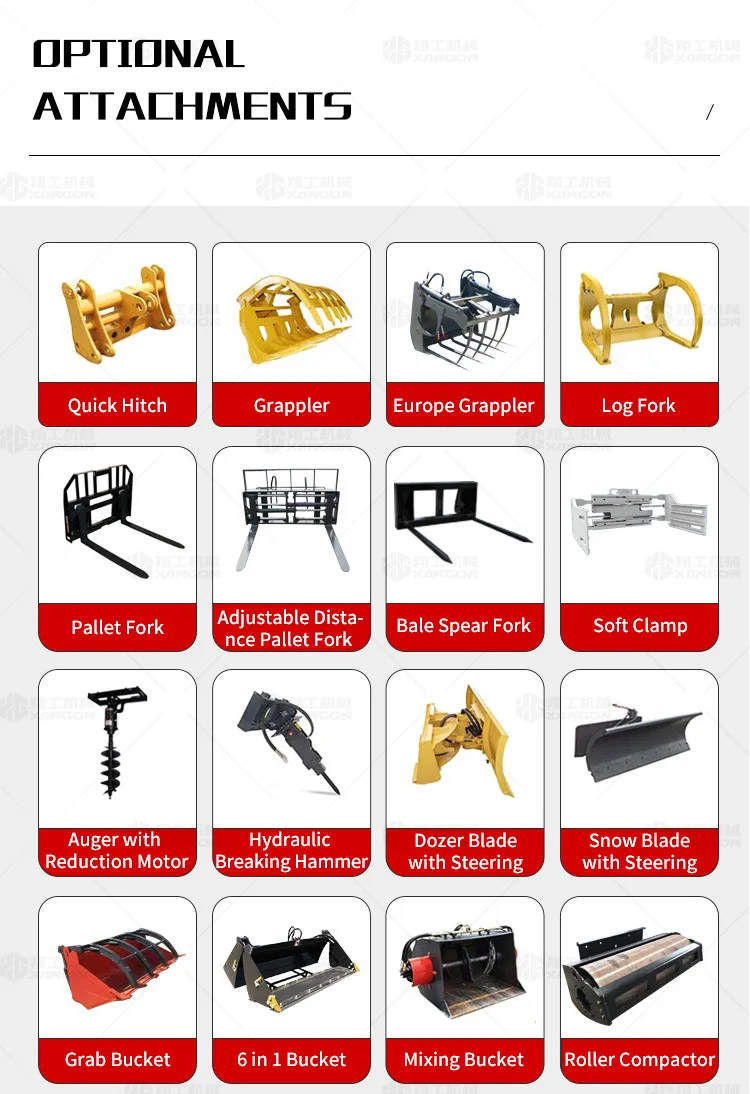

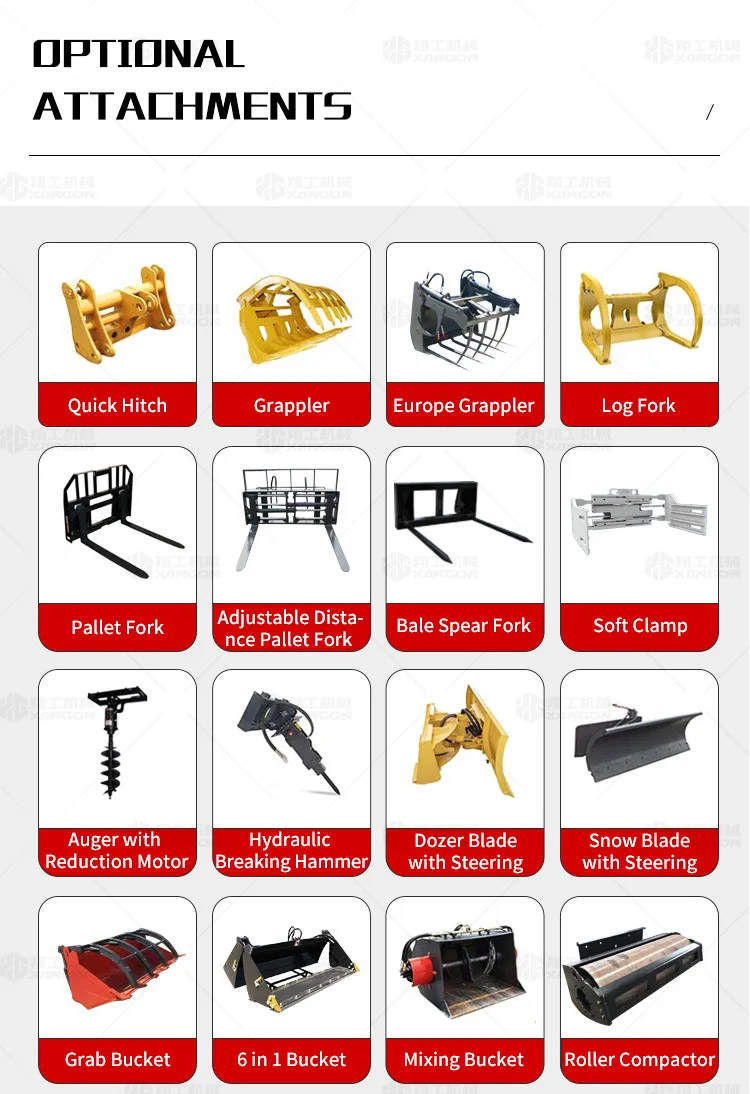

Specialized Loaders: Tailored for specific tasks, such as log handling, snow removal, or pipe handling, these loaders cater to unique industrial requirements.

Applications of Wheel Loaders:

Wheel loaders find diverse applications across numerous industries and scenarios, including:

Construction: Wheel loaders transport and load construction materials such as sand, gravel, and concrete, contributing to project efficiency.

Mining and Quarrying: In mining operations, wheel loaders handle ore, rocks, and earthmoving tasks, vital to extract valuable resources.

Agriculture: On farms, loaders are essential for tasks like handling feed, moving hay bales, and loading grain, streamlining agricultural processes.

Waste Management: Waste and recycling facilities rely on wheel loaders to handle and transport refuse materials, ensuring efficient waste disposal.

Forestry: Specialized loaders are deployed in the forestry industry for log handling and stacking, facilitating wood processing.

Snow Removal: Wheel loaders with snow removal attachments clear roads and parking lots during winter, ensuring safe transportation.

Conclusion:

Wheel loaders stand as the backbone of material handling and construction, renowned for their reliability and versatility. With their sturdy design, powerful engines, and articulated steering, they excel in various industries, from construction and mining to agriculture and waste management. As technology advances, wheel loaders continue to evolve, incorporating enhanced efficiency and safety features, solidifying their status as essential workhorses in the dynamic world of material handling and heavy-duty construction.

Features of Wheel Loaders:

Front-Mounted Bucket: The defining feature of wheel loaders is their front-mounted bucket, designed for scooping, lifting, and transporting a diverse range of materials.

Articulated Steering: Wheel loaders typically feature articulated steering, enabling a tight turning radius, making them exceptionally maneuverable in confined spaces.

Powerful Engine: Equipped with robust engines, wheel loaders deliver the horsepower needed to handle heavy loads and challenging terrains.

Hydraulic Systems: Hydraulic systems control critical loader functions, including raising and lowering the bucket, tilting it, and engaging attachments.

Operator Cabin: Modern wheel loaders are equipped with enclosed, climate-controlled operator cabins, enhancing operator comfort and safety.

Components of a Wheel Loader:

Bucket: The front-mounted bucket is the primary attachment for scooping and carrying materials. Different bucket sizes cater to various tasks.

Boom Arms: Responsible for raising and lowering the bucket, boom arms provide articulation and pivot for versatile loading angles.

Hydraulic System: The hydraulic system powers loader movements, ensuring precise bucket control and articulation.

Engine: A robust engine supplies the necessary horsepower to move heavy loads and operate hydraulic functions.

Transmission: The transmission system manages power distribution to the wheels for efficient movement.

Types of Wheel Loaders:

Compact Wheel Loaders: Smaller and highly maneuverable, these loaders are ideal for tasks in landscaping, agriculture, and light construction.

Standard Wheel Loaders: Versatile in size, standard wheel loaders are used in construction, agriculture, mining, and general material handling.

Large Wheel Loaders: Heavy-duty machines designed for mining, quarrying, and major construction projects, capable of handling substantial loads.

Waste and Recycling Loaders: Customized for waste management and recycling operations, these loaders have specialized attachments for handling refuse.

Specialized Loaders: Tailored for specific tasks, such as log handling, snow removal, or pipe handling, these loaders cater to unique industrial requirements.

Applications of Wheel Loaders:

Wheel loaders find diverse applications across numerous industries and scenarios, including:

Construction: Wheel loaders transport and load construction materials such as sand, gravel, and concrete, contributing to project efficiency.

Mining and Quarrying: In mining operations, wheel loaders handle ore, rocks, and earthmoving tasks, vital to extract valuable resources.

Agriculture: On farms, loaders are essential for tasks like handling feed, moving hay bales, and loading grain, streamlining agricultural processes.

Waste Management: Waste and recycling facilities rely on wheel loaders to handle and transport refuse materials, ensuring efficient waste disposal.

Forestry: Specialized loaders are deployed in the forestry industry for log handling and stacking, facilitating wood processing.

Snow Removal: Wheel loaders with snow removal attachments clear roads and parking lots during winter, ensuring safe transportation.

Conclusion:

Wheel loaders stand as the backbone of material handling and construction, renowned for their reliability and versatility. With their sturdy design, powerful engines, and articulated steering, they excel in various industries, from construction and mining to agriculture and waste management. As technology advances, wheel loaders continue to evolve, incorporating enhanced efficiency and safety features, solidifying their status as essential workhorses in the dynamic world of material handling and heavy-duty construction.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)