- Home >

- Product >

- Loaders >

- Wheel loaders >

- View Details

XG-912 Wheel Loaders Easy to operate

The bulk handling and loading of grain, farm yard manure and biomass digestate requires a dedicated heavy duty machine to cope with the heavy payloads and repetitive duty cycles.

- XG-912

- ZHUOXIN

- Wheel Loaders

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- The ZX Series New wheel loaders are perfectly suited to these tasks and the range now features the flagship heavyweight W190C model, wheel loaders with Industrial engine and available in Long Reach and Z-Bar configurations.

Description

The wheel loader traces its heritage to the introduction 65 years ago of a scoop situated at the back-end of an ag tractor next to the larger rear wheels. The operator platform of the tractor was reversed so the operator looked down on the one-ton capacity bucket. The positioning of the bucket over the larger wheels gave the loader more capacity and digging force. The new machine was an innovation by a precursor company of Volvo Group, which has gone on to produce many generations of wheel loaders.

How will you employ the wheel loader?

If you are a general contractor with a fleet of equipment and a specific repetitive task in mind, you know what model of machine you need. For everyone else, some consideration of tasks is in order. How will you use a wheel loader? You should make a list of probable applications and rank them by how often they will recur. Will you blade more than scoop? Blow snow more often than lift bales? For optimal performance of any task, several factors come into play including horsepower, weight, hydraulic flow, and configuration. Shop for a machine that will best suit your work.

Hydraulic flow wheel loader

The volume and pressure of hydraulic fluid pumped through a wheel loader’s system regulates what it can accomplish. Flow is measured in gallons per minute (gpm). Many manufacturers offer standard and optional high-flow hydraulic systems. A standard flow (17 to 24 gpm) system will operate buckets and grapples. High-flow systems (30 to 40 gpm) with higher pounds-per-square-inch ratings are needed to run more demanding attachments, such as mulchers and snow blowers. While standard flow hydraulics sometime will give the semblance of operating hi-flow attachments, performance will be disappointing. Know what hydraulic flow you will require.

Load capacity wheel loader

Buckets are the most common attachment on a wheel loader so knowing the capacity of your loader is important. Capacity usually is rated in cubic yards — the equivalent of material piled a yard high, yard wide and yard deep — or, roughly, nine wheelbarrow loads. Subcompact loaders are limited to a cubic yard of material or less. Compact machines typically can lift two or three cubic yards, while midsize and larger loaders can lift up to 20 cubic yards or more. Bucket size is determined by engine output, hydraulic flow capacity and machine weight. Get a loader with the capacity you need.

Lift height wheel loader

Wheel loaders have lift heights commensurate with their size and weight. Compact loaders are designed for relatively short lifts (raising potted plants onto a trailer, loading pallets, hauling and dumping dirt). Larger loaders can extend over the sides of dump trucks, reach high shelving, or lift long upright materials into position. It follows that smaller machines generally can raise a bucket 8 to 10 feet into the air with midsize units going up 12 to 14 feet. Bigger loaders can reach up 25 feet or more. Make sure your loader can lift its arms high enough to perform your desired tasks.

The mini wheel loader is a kind of earth and stone construction machinery widely used in highways, railways, hydropower, construction, ports, mines and other construction projects.

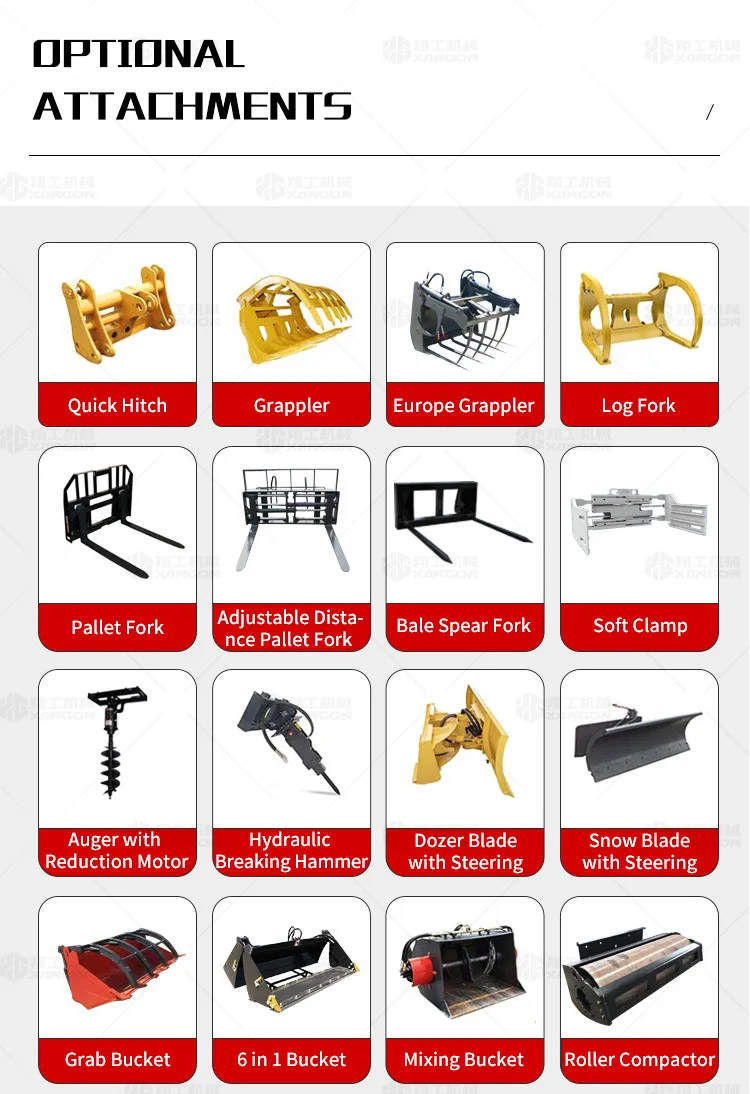

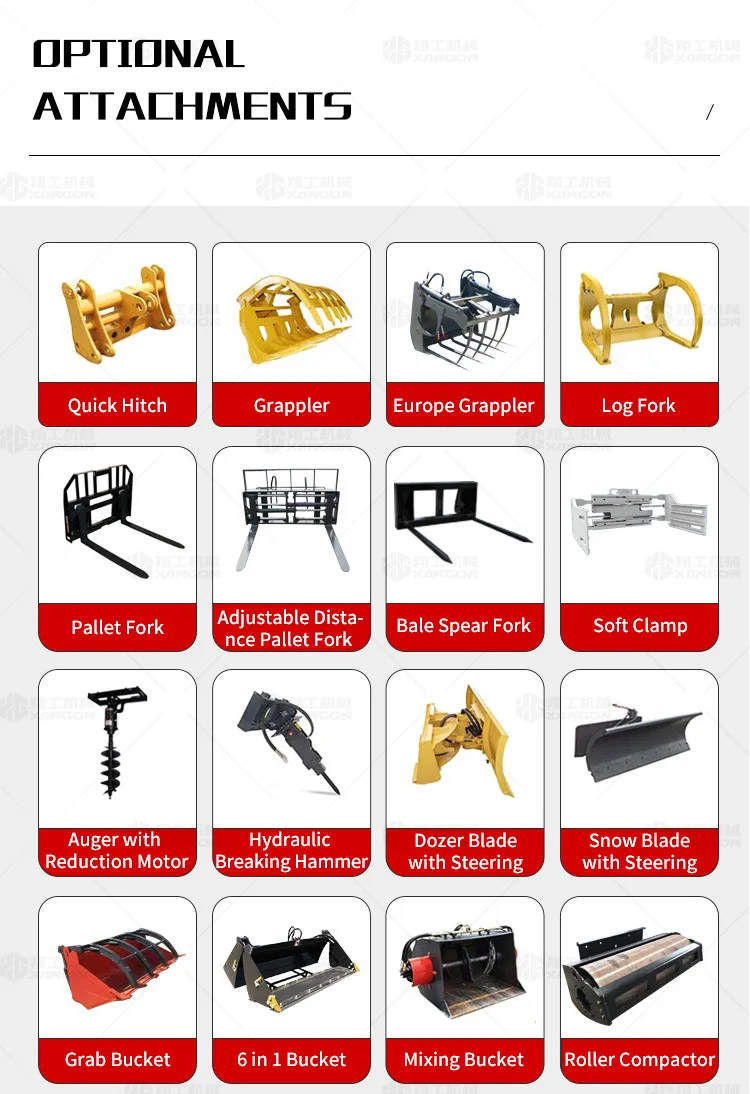

It is used for loading and unloading bulk materials such as soil, sand, lime, coal, etc. It can also be used for light shovel and digging operations on ore and hard soil. Different auxiliary working devices can also be used for bulldozing, lifting and other materials such as timber loading and unloading operations. In the construction of roads, especially high-grade highways, small loaders are used for filling and excavating roadbed works, asphalt mixtures and aggregate and loading of cement concrete yards. In addition, it can also carry out operations such as pushing soil, leveling the ground and pulling other machinery. Because the mini wheel loader has the advantages of fast working speed, high efficiency, good maneuverability, and light operation, it has become one of the main types of earth and stone construction in engineering construction.

How will you employ the wheel loader?

If you are a general contractor with a fleet of equipment and a specific repetitive task in mind, you know what model of machine you need. For everyone else, some consideration of tasks is in order. How will you use a wheel loader? You should make a list of probable applications and rank them by how often they will recur. Will you blade more than scoop? Blow snow more often than lift bales? For optimal performance of any task, several factors come into play including horsepower, weight, hydraulic flow, and configuration. Shop for a machine that will best suit your work.

Hydraulic flow wheel loader

The volume and pressure of hydraulic fluid pumped through a wheel loader’s system regulates what it can accomplish. Flow is measured in gallons per minute (gpm). Many manufacturers offer standard and optional high-flow hydraulic systems. A standard flow (17 to 24 gpm) system will operate buckets and grapples. High-flow systems (30 to 40 gpm) with higher pounds-per-square-inch ratings are needed to run more demanding attachments, such as mulchers and snow blowers. While standard flow hydraulics sometime will give the semblance of operating hi-flow attachments, performance will be disappointing. Know what hydraulic flow you will require.

Load capacity wheel loader

Buckets are the most common attachment on a wheel loader so knowing the capacity of your loader is important. Capacity usually is rated in cubic yards — the equivalent of material piled a yard high, yard wide and yard deep — or, roughly, nine wheelbarrow loads. Subcompact loaders are limited to a cubic yard of material or less. Compact machines typically can lift two or three cubic yards, while midsize and larger loaders can lift up to 20 cubic yards or more. Bucket size is determined by engine output, hydraulic flow capacity and machine weight. Get a loader with the capacity you need.

Lift height wheel loader

Wheel loaders have lift heights commensurate with their size and weight. Compact loaders are designed for relatively short lifts (raising potted plants onto a trailer, loading pallets, hauling and dumping dirt). Larger loaders can extend over the sides of dump trucks, reach high shelving, or lift long upright materials into position. It follows that smaller machines generally can raise a bucket 8 to 10 feet into the air with midsize units going up 12 to 14 feet. Bigger loaders can reach up 25 feet or more. Make sure your loader can lift its arms high enough to perform your desired tasks.

The mini wheel loader is a kind of earth and stone construction machinery widely used in highways, railways, hydropower, construction, ports, mines and other construction projects.

It is used for loading and unloading bulk materials such as soil, sand, lime, coal, etc. It can also be used for light shovel and digging operations on ore and hard soil. Different auxiliary working devices can also be used for bulldozing, lifting and other materials such as timber loading and unloading operations. In the construction of roads, especially high-grade highways, small loaders are used for filling and excavating roadbed works, asphalt mixtures and aggregate and loading of cement concrete yards. In addition, it can also carry out operations such as pushing soil, leveling the ground and pulling other machinery. Because the mini wheel loader has the advantages of fast working speed, high efficiency, good maneuverability, and light operation, it has become one of the main types of earth and stone construction in engineering construction.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)